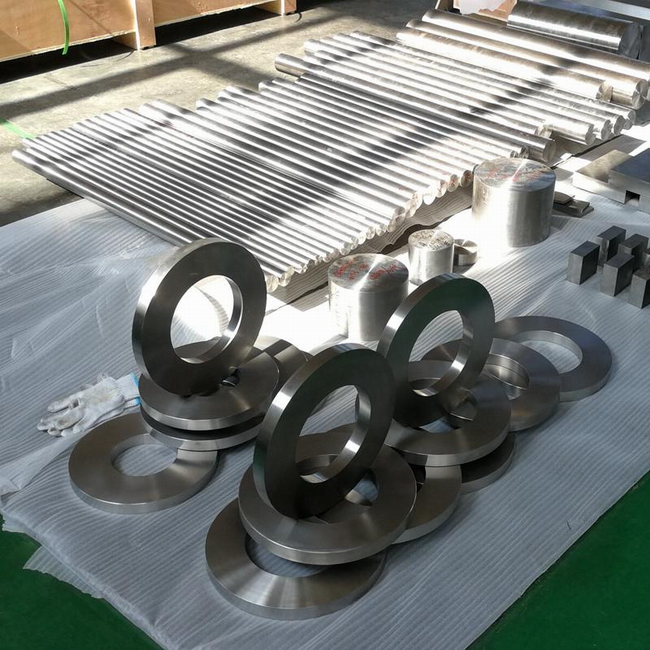

Titanium bar

TITANIUM BARS / RODS

Titanium Round Bar products as per ASTM B348/ASME SB348 are available in Grades 1, 2, 3, 4, Ti6AL4V and other titanium grades in sizes up to diameter 500mm.

Rectangular and square sizes are also available.

We supply aerospace grades

like AMS 4928, AMS 4911, AMS 2631, AMS 4901, AMS 4907, AMS 4919, AMS 6931, AMS T 9046, AMS T 9047 and

international standards

like ASTM B 337, ASTM B 338, ASTM B 381, ASTM F 67, ASTM F 136, ASTM B348, ASTM B265 and

pipes, fittings & flanges with

NORSOK M630 Rev 2 MDS T01 specifications at very competitive titanium prices.

Description

Titanium bar are divided into pure titanium bar and titanium alloy bars. For pure titanium bars we mainly provide Gr1, Gr2, Gr4 and other grades; we provide titanium alloy bars of Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 etc.

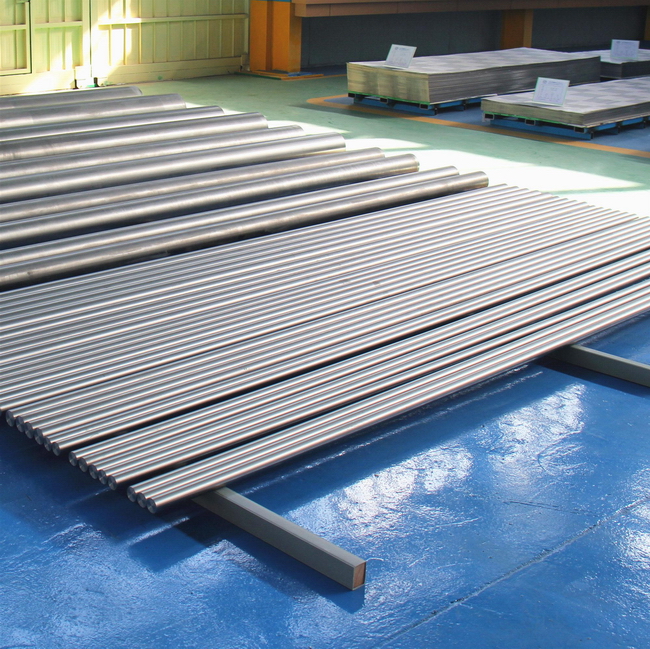

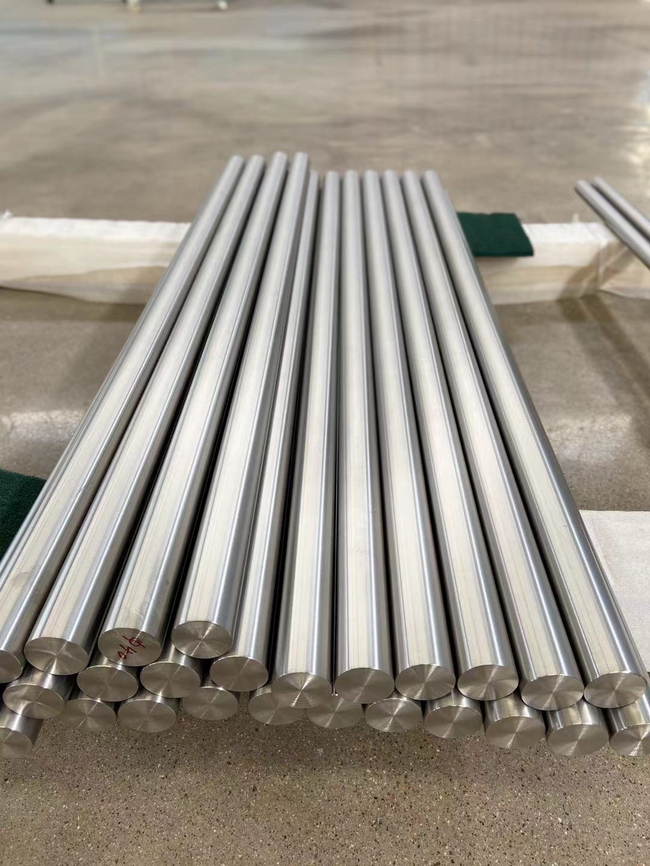

Titanium bar is one of the most common kinds of titanium products. It is the base material of many titanium products for further processing. The larger diameter titanium bar can be directly produced by forging. We have the free forging equipment which helps to produce the large size titanium bars. In the process of forging, the titanium ingot is deformed uniformly in a short time from inside to outside, improved the titanium mechanical properties. The material quality has been greatly improved compared to the hammer forging; Small diameter titanium bars can be produced after multiple rolling and annealing, and removed titanium oxide layer by mechanical processing in the end.

We provide turning surface and polished surface of titanium bar. At the same time, we have plenty of titanium bars inventory in different sizes, for those customers with urgent demands on the time of delivery and the customers with a small amount needed.

UNS No.

|

|

UNS No. |

|

UNS No. |

|

Gr1 |

UNS R50250 |

CP-Ti |

Gr11 |

UNS R52250 |

Ti-0.15Pd |

|

Gr2 |

UNS R50400 |

CP-Ti |

Gr12 |

UNS R53400 |

Ti-0.3Mo-0.8Ni |

|

Gr4 |

UNS R50700 |

CP-Ti |

Gr16 |

UNS R52402 |

Ti-0.05Pd |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

Gr23 |

UNS R56407 |

Ti-6Al-4V ELI |

|

Gr9 |

UNS R56320 |

Ti-3Al-2.5V |

|

|

|

Specifications

|

Grade |

Status |

Diameter(mm) |

Length(mm) |

|

Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11,Gr12,Gr16,Gr23 |

Hot rolled (R) |

6~115 |

10~6000 |

|

Cold rolled (Y) |

|

Annealed (M) |

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

C

(≤) |

O

(≤) |

N

(≤) |

H

(≤) |

Fe

(≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements

Max. each |

Other Elements

Max. total |

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

Tensile strength

Min |

Yield strength

Min (0.2%,offset) |

Elongation in 4D

Min (%) |

Reduction of Area

Min (%) |

|

ksi |

MPa |

ksi |

MPa |

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

Tolerance (mm)

|

Diameter |

Size variations |

Out of round, Out of square |

|

6.0~8.0 |

±0.13 |

0.20 |

|

8.0~11.0 |

±0.15 |

0.23 |

|

11.0~16.0 |

±0.18 |

0.25 |

|

16.0~22.0 |

±0.20 |

0.30 |

|

22.0~25.0 |

±0.23 |

0.33 |

|

25.0~28.0 |

±0.25 |

0.38 |

|

28.0~32.0 |

±0.28 |

0.41 |

|

32.0~35.0 |

±0.30 |

0.46 |

|

35.0~38.0 |

±0.36 |

0.53 |

|

38.0~50.0 |

±0.40 |

0.58 |

|

50.0~65.0 |

+0.79 |

0.58 |

|

65.0~90.0 |

+1.19 |

0.89 |

|

90.0~115.0 |

+1.59 |

1.17 |

We can provide round bar, square bar, hexagonal bar, eight square bar, flat bar etc.

Testing

-

Chemical composition test

-

Physical properties test

-

Appearance defects inspection

-

Ultrasonic flaw detection

-

Eddy current testing

Packaging

In order to avoid the titanium bars have any collision in transit or damage, usually wrapped with pearl cotton (expandable polyethylene), and then packed into wooden case for delivery.