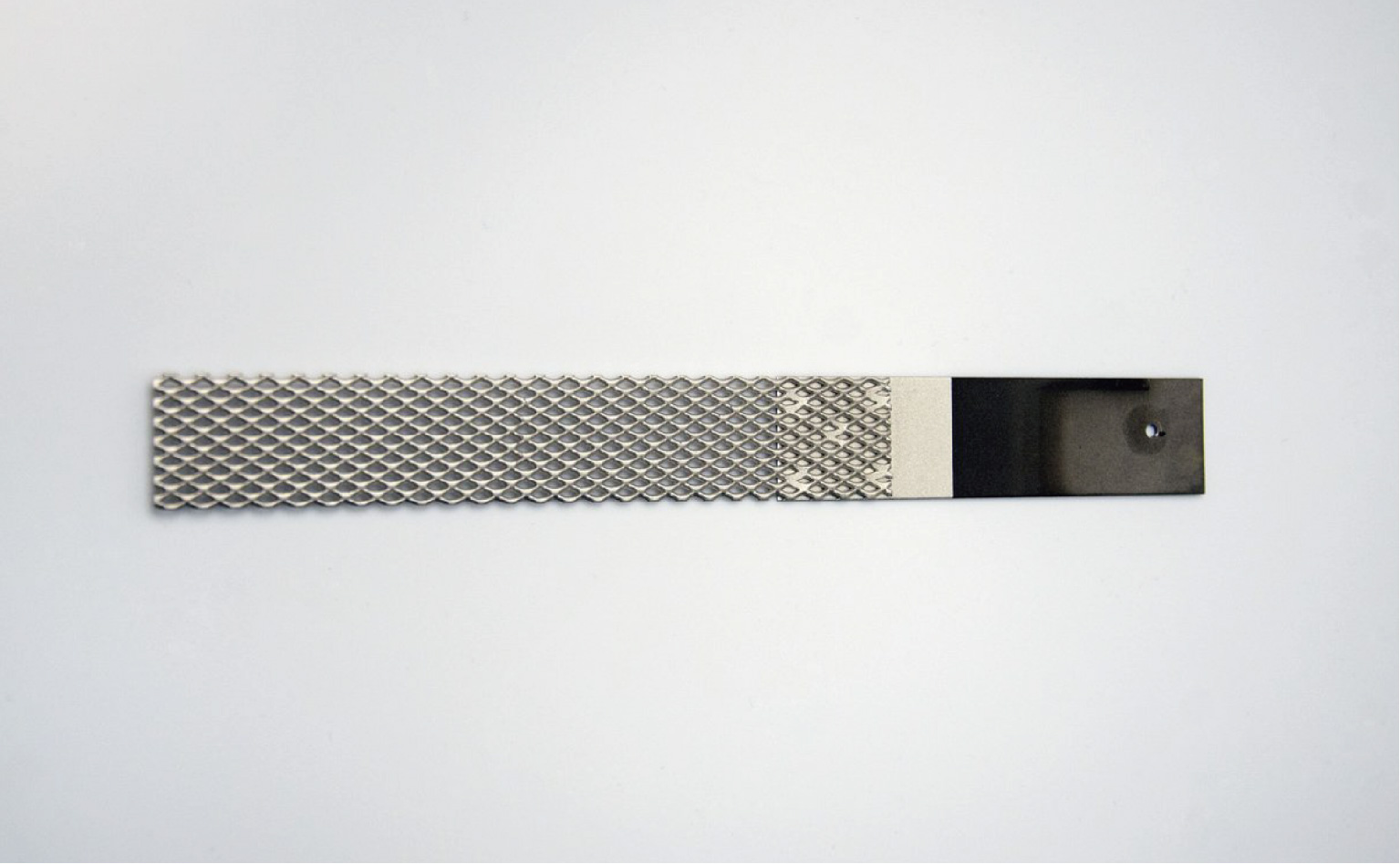

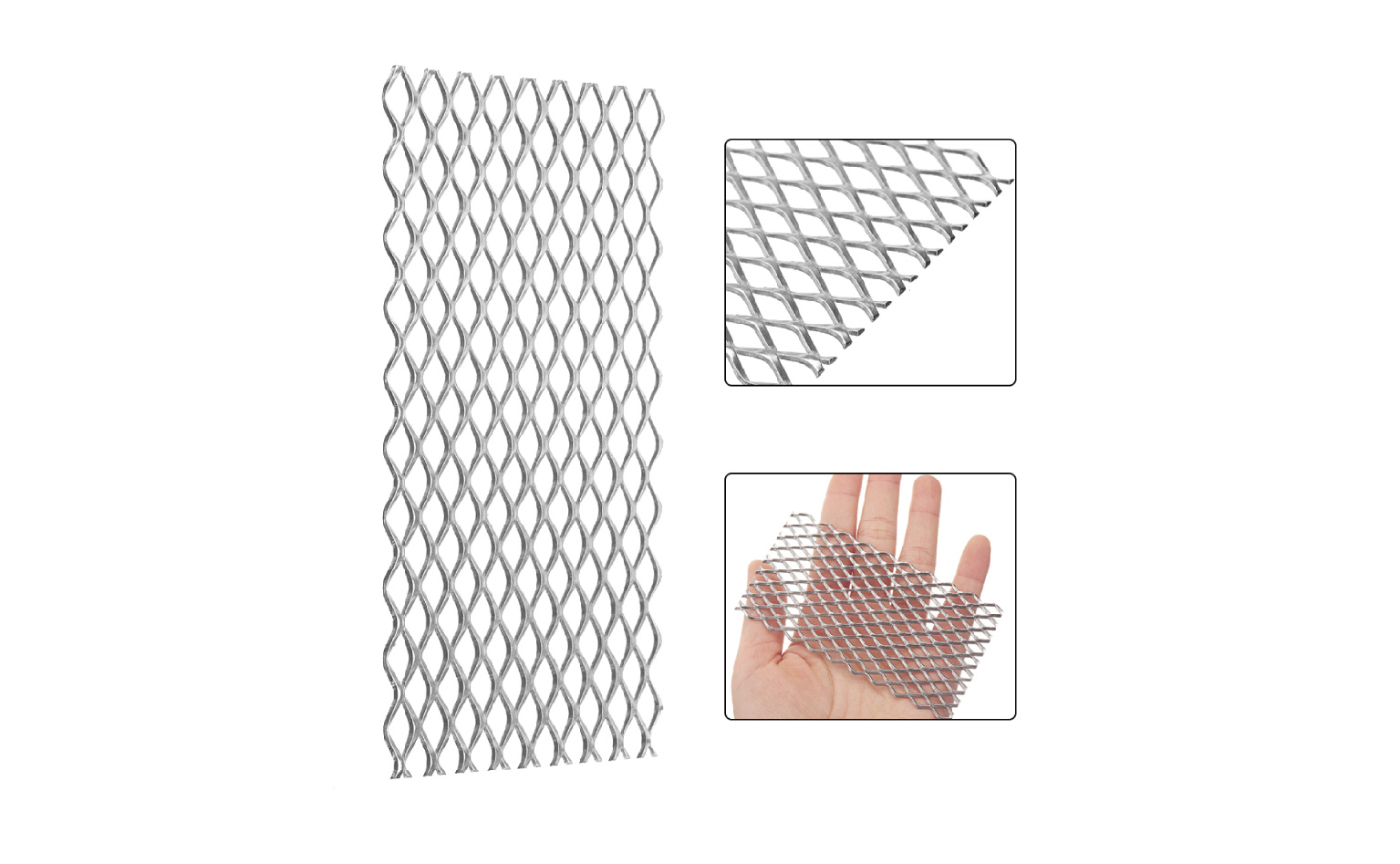

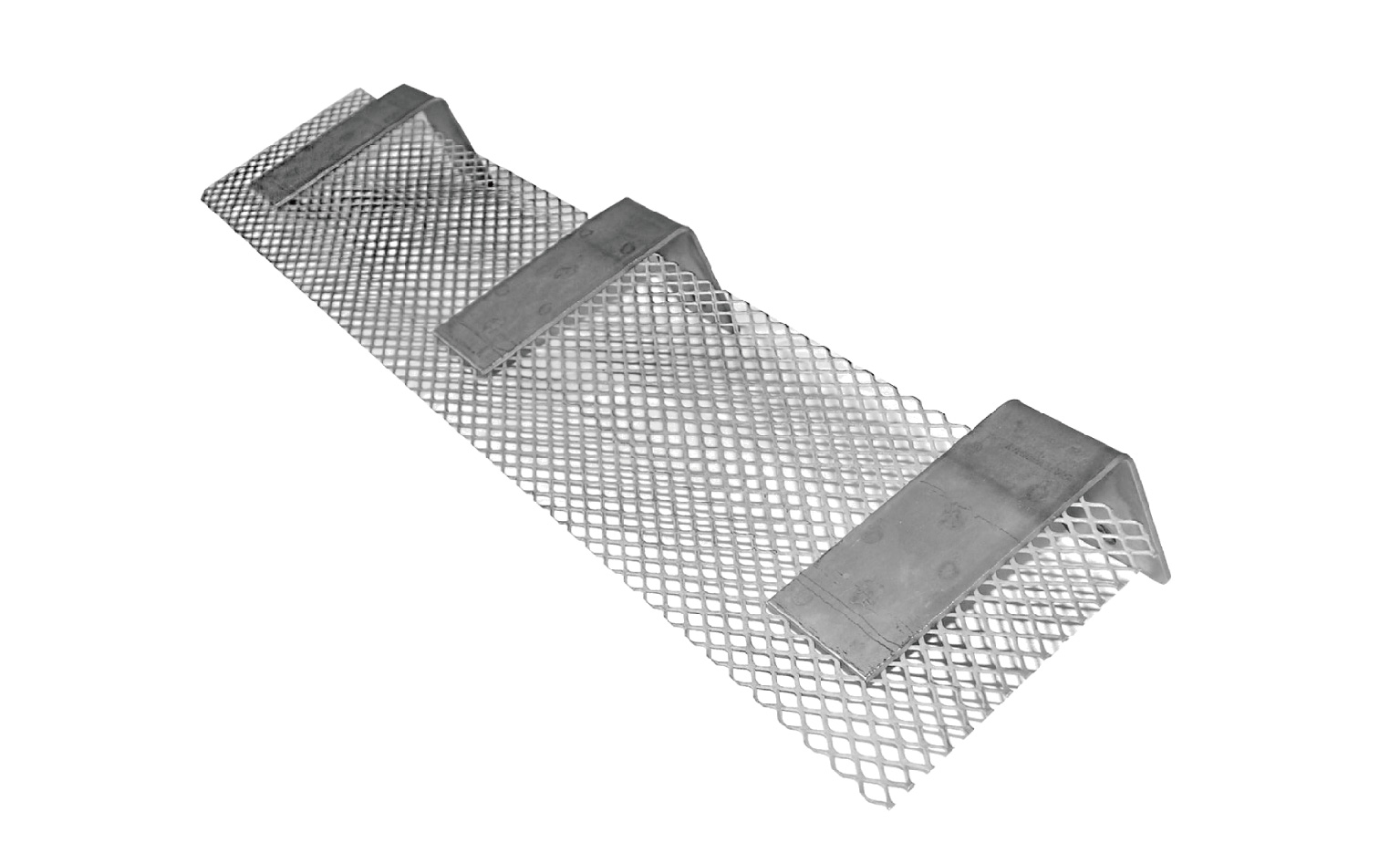

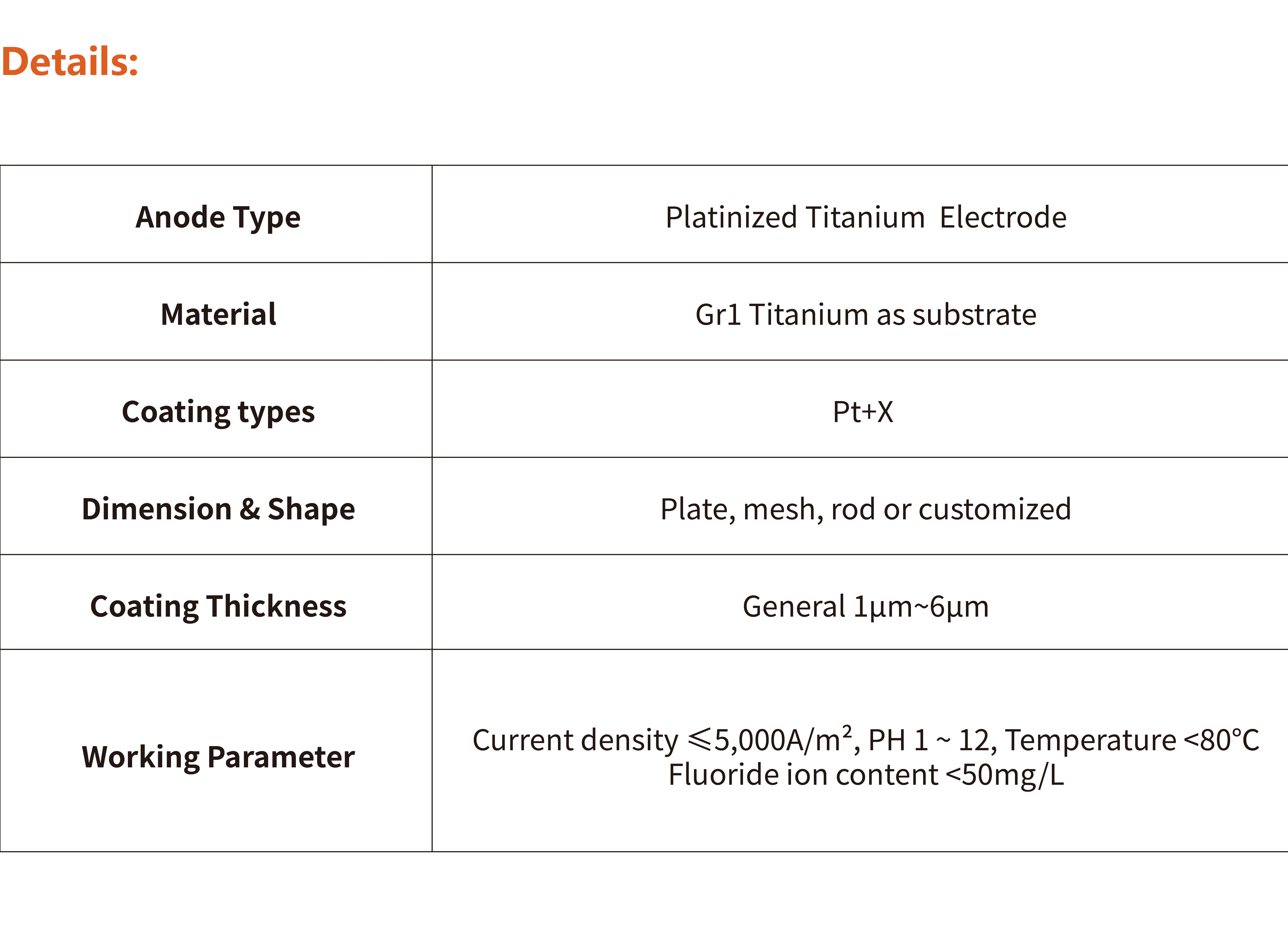

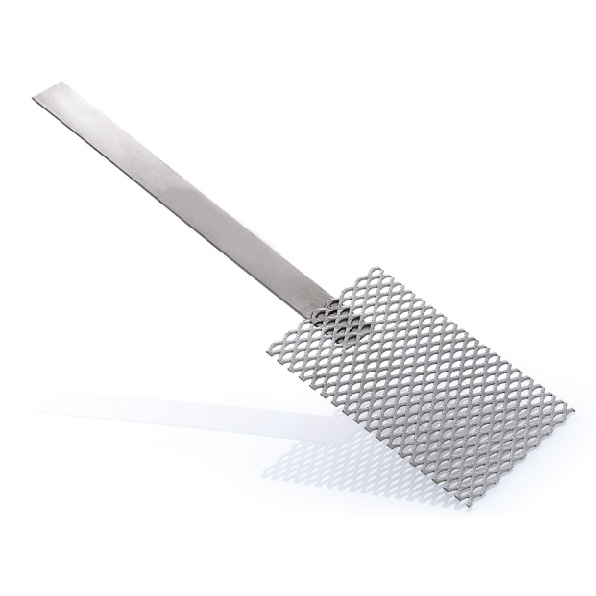

This electrode is based on titanium metal as anodes in the form of nets, plates, rods, filaments, tubes, wire and so on.The thickness of the standard platinum layer is 2-5μm. Under higher requirements, the thickness of the platinum layer can reach 20μm.

The service life of the platinum-plated titanium anode depends on the working medium (electrolyte) and the current strength (current density) of the anode. The current density should not exceed 75A /dm2. Below this value, the wear of the platinum layer is very small, and the service life of the anode can also be estimated. According to experience, the wear of the platinum layer is about 1-4 grams per million amp-hours in a fluorine-free chromium plating solution. When the current density is higher than 75A/dm2.