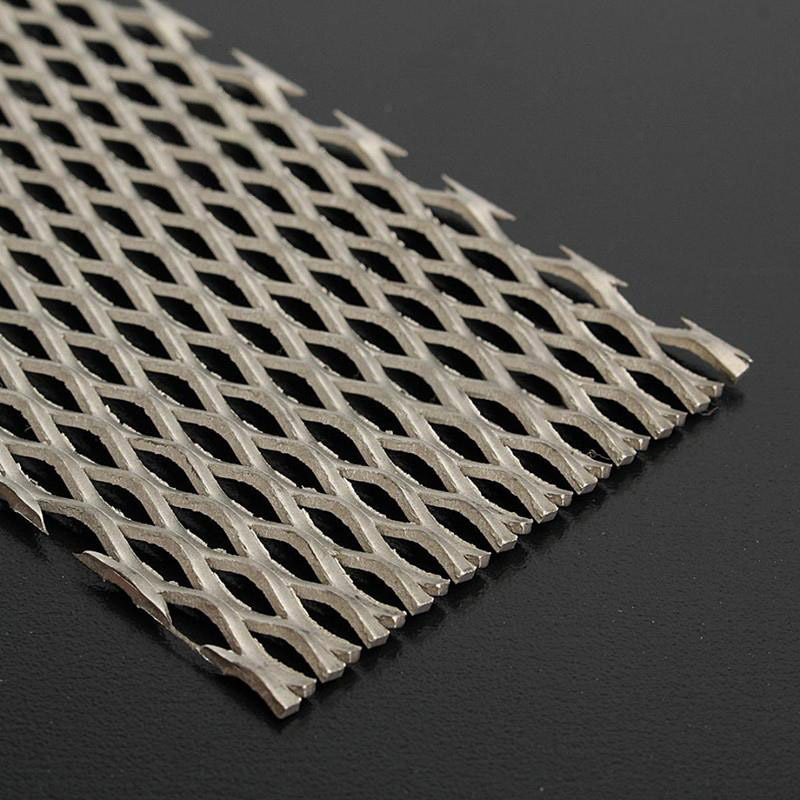

The Platinized Titanium Mesh Anode is mostly used, because it has outstanding practical performance, such as strong ability of ionization release, good exchange of electrolyte, close structure and light weight, etc.

Substrate: Pure Titanium;

Grade: Gr.1 (DIN 3.7025) or Gr.2 (DIN 3.7035);

Substrate Shape: Mesh, Plate,Sheet, Tube, Rod, Wire or customized;

Dimension and Structure: Customized;

Thickness of Platinum coating: 0- 20 µm;

Current Density: 75A/dm2 max;

Scope of Application: Anode/Two-way Electrode;

PH: 0 – 11;

Plating Temperature: 60 °C max;

Properties comparison between platinized titanium electrode and the other electrode in the cathode protection:

| Material | Work Environment |

The max work current density

A/m2

|

Consumption rates

kg/A·a

|

| High Silicon Iron | Sea | 50 | 0.3-1.0 |

| Graphite | Fresh water, Soil | 10 | 0.05-0.2 |

| Sea | 10 | 0.16 | |

| Fresh water | 2.5 | 0.04 | |

| Lead-silver alloy | Sea | 30-300 | 0.03 |

| Lead-silver platinum | Sea | 30-300 | 0.03 |

| Platinized titanium | Sea, Fresh water | 1000 | --- |

| Titanium/Mixed metal oxides | Sea | 600 | --- |

Specifications:

| Description | PTA |

MMOA |

| PH Level: (between) | 1.0-12.0 | 1.0-12.0 |

| Pt / mixed oxide layer tk. (µm) | 0-10.0 | 8.0 |

| Fluorides content (max) | 50mg/l | 50mg/l |

| Allowable current (max) | 50A/dm2 | 50A/dm2 |

Application:

Electrosynthesis;

Chlorate & perchlorate production;

Eectro-chlorination;

Electroplating( Au,Ag, Pd);

Cathodic protection;

Sewage treatment.

Platinized titanium anode combines the excellent electrochemical performance of Platinum and higher anticorrosion property. Comparing with the other soluble electrode and Lead anode, it has the following advantages.

Advantages:

Flexibility to meet various using needs;

Produce complex shape of anode;

Energy saving;

Light weight (especially the mesh grid anode);

Longer working life under higher current density;

Firm titanium structure, less deformation;

Second platinized allowed;

Uniform deposit, final products with high quality.