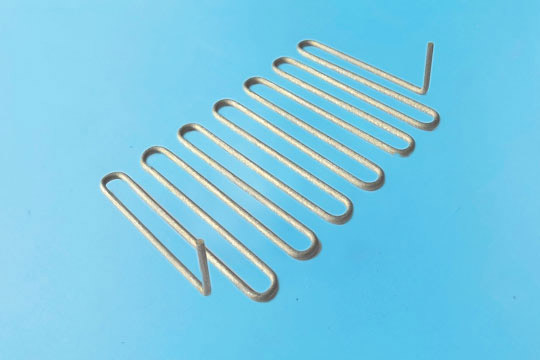

Molybdenum Heating Element

Molybdenum is refractory metal and is ideally suited for use at high temperatures. With their special properties, molybdenum is the perfect choice for components in the furnace construction industry. Molybdenum heating elements (molybdenum heater) are mostly used for high-temperature furnaces, sapphire growth furnaces, and other high-temperature furnaces.

Standard: ASTM B387

Material: Mo-1, Mo-2, >99.95%

Density: >10.20g/cc

Application temperature environment: <1900°C

Molybdenum Heating Element Applications

Molybdenum heating elements can be expected, under proper conditions, to maintain temperatures up to approximately 1900°C. These are widely applied in high-temperature resistance furnaces, sapphire growth furnaces.

Molybdenum Heating Element Specifications

Molybdenum heating elements can be welded and sliced. Molybdenum heating elements should be made of one continuous piece of wire, rod, or ribbon. Standard availability is described below. Other sizes and tolerances are available.

|

Diameter (mm) |

Width (mm) |

Height (mm) |

|

Size |

Tolerance |

Size |

Tolerance |

Size |

Tolerance |

|

3 |

±0.1 |

<650 |

±5.0 |

<1200 |

±10.0 |

|

4 |

±0.1 |

<600 |

±5.0 |

<1150 |

±10.0 |

|

5 |

±0.1 |

<550 |

±5.0 |

<1100 |

±10.0 |

|

6 |

±0.2 |

<550 |

±5.0 |

<1050 |

±10.0 |

|

7 |

±0.2 |

<500 |

±5.0 |

<1000 |

±10.0 |

|

8 |

±0.2 |

<500 |

±5.0 |

<950 |

±5.0 |

|

9 |

±0.2 |

<450 |

±5.0 |

<900 |

±5.0 |

Molybdenum Heating Element Properties

High operating temperatures

Outstanding creep resistance

High level of dimensional stability

Extremely pure

Excellent corrosion resistance

Low coefficient of expansion