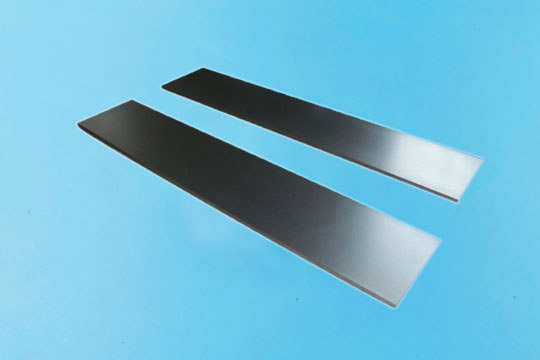

| Condition: | Annealed |

|---|---|

| Size | Thickness: 0.07-10 mm |

| Width: 30-1000 mm | |

| Length: 30-3000 mm | |

| Material | UNS R05200, UNS R05400 |

| Standard | ASTM B708-98 |

| Purity | ≥99.95% or 99.99% |

Sizes/Tolerance(mm max)

| Thickness | Tolerance | Width | Tolerance | Length | Tolerance | |

|---|---|---|---|---|---|---|

| GradeⅠ | gradeⅡ | |||||

| >0.15-0.2 | ±0.015 | ±0.02 | 50-300 | ±2.0 | 100-1000 | ±2.0 |

| >0.2-0.3 | ±0.020 | ±0.03 | 50-300 | ±1.0 | 100-1000 | ±2.0 |

| >0.3-0.5 | ±0.030 | ±0.04 | 50-500 | ±1.0 | 100-1500 | ±2.0 |

| >0.5-0.8 | ±0.040 | ±0.06 | 50-500 | ±1.0 | 50-2000 | ±2.0 |

| >0.8-1.0 | ±0.060 | ±0.08 | 50-500 | ±1.0 | 50-2000 | ±2.0 |

| >1.0-1.5 | ±0.080 | ±0.10 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >1.5-2.0 | ±0.120 | ±0.14 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >2.0-3.0 | ±0.160 | ±0.18 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >3.0-4.0 | ±0.180 | ±0.20 | 50-500 | ±1.0 | 50-1500 | ±1.0 |

| >4.0-6.0 | ±0.200 | ±0.24 | 50-350 | ±1.0 | 50-1500 | ±1.0 |

| Grade | Chemical Composition, Max | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | Ta | |

| Ta1 | 0.005 | 0.005 | 0.002 | 0.005 | 0.002 | 0.002 | 0.005 | 0.015 | 0.004 | 0.002 | 0.005 | Balance |

| Ta2 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.010 | 0.030 | 0.010 | 0.002 | 0.010 | Balance |

| FTa1 | 0.005 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.005 | 0.020 | 0.003 | 0.002 | 0.005 | Balance |

| FTa2 | 0.010 | 0.030 | 0.010 | 0.005 | 0.002 | 0.002 | 0.010 | 0.035 | 0.003 | 0.002 | 0.010 | Balance |

| Remark | Ta1, and Ta2 are made in ingot culture, and FTa1, and FTa2 are made in the vertical melting strip. | |||||||||||