| Description | Mainly Content (%) | Impurities (%, Maximum) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| TaNb3 | Reminder | 2.5~3.5 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb20 | Reminder | 17.0~23 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb30 | Reminder | 27.0~33 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.0015 | 0.004 |

| TaNb40 | Reminder | 37.0~43 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.001 | |

Grade: TNb-W-Ta TNb-W-Mo-Zr TTa-W TNb-W TTa-Nb TNb-Zr

| Grade | TNb-W-Ta | TNb-W-Mo-Zr | TTa-W | TNb-W | TTa-Nb | TNb-Zr | |

|---|---|---|---|---|---|---|---|

|

Impurity Content , %,Max |

C | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| O | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| N | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Application | For cast ingot and super alloys | ||||||

Remarks: Add element ratios can be added as required by the users’ special requirements to be agreed upon by the supplier and buyer.

Chemical Composition

Sizes/Tolerance(mm.max)

Φ(0.2-2.0mm)±0.01mm;Φ(2.0-3.0mm)±0.02mm

| Grade | Chemical Compositions,Max | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta | |

| TaNb-1 | 0.01 | 0.02 | 0.01 | 0.0015 | 3-50 | 0.01 | 0.01 | 0.05 | 0.02 | 0.005 | 0.01 | Balance |

Special requirements to be agreed upon by the supplier and buyer

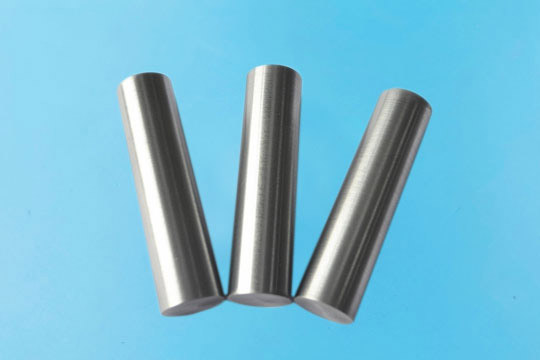

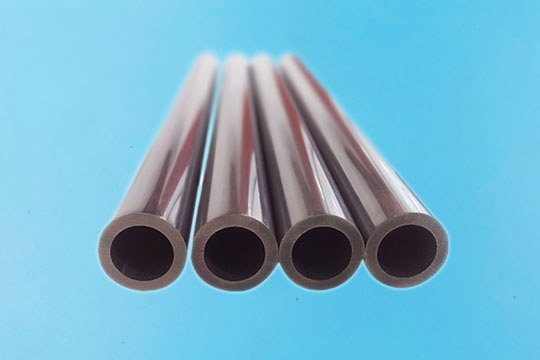

Applications: For heating elements in high-temperature vacuum furnaces

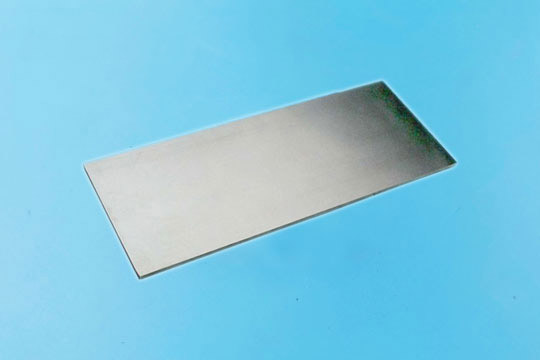

Applications: For the insulation shields in high-temperature vacuum furnaces

Applications: For rare-earth metallurgy, load plates for anodes of tantalum and niobium, and insulation and niobium electrolytic capacitors sintered at high-temperatures, and corrosion-resistant containers in chemical industries.