| <span "="" style="padding: 0px; margin: 0px;"> | UNS No. |

|

UNS No. | ||

| Gr1 | UNS R50250 | CP-Ti | Gr11 | UNS R52250 | Ti-0.15Pd |

| Gr2 | UNS R50400 | CP-Ti | Gr12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| Gr4 | UNS R50700 | CP-Ti | Gr16 | UNS R52402 | Ti-0.05Pd |

| Gr7 | UNS R52400 | Ti-0.20Pd | Gr23 | UNS R56407 | Ti-6Al-4V ELI |

| Gr9 | UNS R56320 | Ti-3Al-2.5V |

|

|

|

| Grade | Status | Specification | ||

|

Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 |

Hot Rolled(R) Cold Rolled(Y) Annealed(M) Solution treatment(ST) |

Thickness(mm) | Width(mm) | Length(mm) |

| 0.01~0.1 | 30~300 | ≥500 | ||

| Grade | Chemical composition, weight percent (%) | ||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al | V | Pd | Ru | Ni | Mo |

Other Elements Max. each |

Other Elements Max. total |

|

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

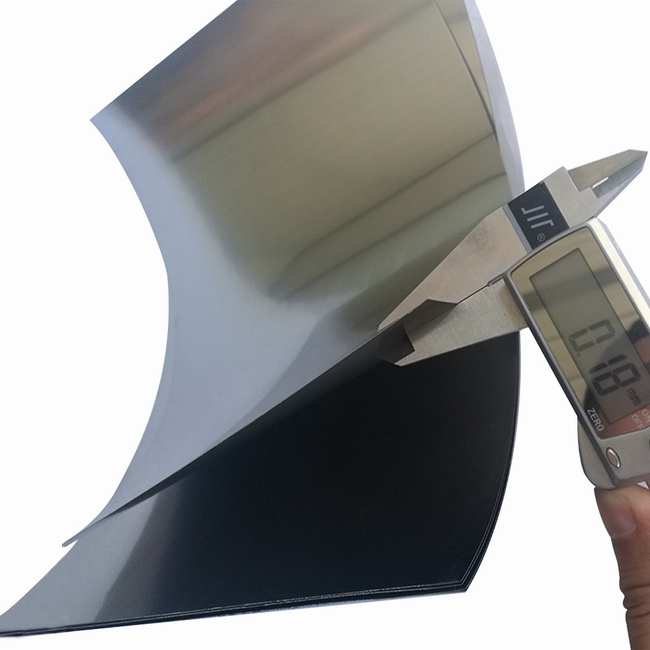

| Thickness | Thickness tolerance | Width tolerance | Length tolerance |

| 0.01~0.02 | ±0.003 | ±0.5 | ±10.0 |

| 0.03~0.05 | ±0.005 | ±0.5 | ±10.0 |

| 0.06~0.07 | ±0.007 | ±0.5 | ±10.0 |

| 0.08~0.1 | ±0.010 | ±0.5 | ±10.0 |