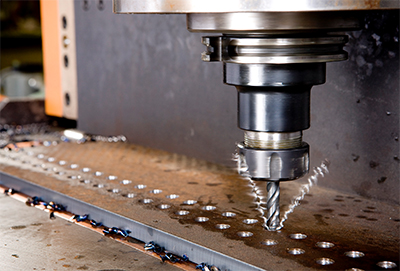

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole in solid materials. The drill bit is a multipoint, end cutting tool. It cuts by applying pressure and rotation to the workpiece, which forms chips at the cutting edge.

Under normal usage, swarf is carried up and away from the tip of the drill bit by the fluting of the drill bit. The cutting edges produce more chips which continue the movement of the chips outwards from the hole. This is successful until the chips pack too tightly, either because of deeper than normal holes or insufficient backing off (removing the drill slightly or totally from the hole while drilling). Cutting fluid is sometimes used to ease this problem and to prolong the tools life by cooling and lubricating the tip and chip flow. Coolant may be introduced via holes through the drill shank, which is common when using a gun drill. When cutting aluminum in particular, cutting fluid helps ensure a smooth and accurate hole while preventing the metal from grabbing the drill bit in the process of drilling the hole.

For heavy feeds and comparatively deep holes oil-hole drills can be used, with a lubricant pumped to the drill head through a small hole in the bit and flowing out along the fluting. A conventional drill press arrangement can be used in oil-hole drilling, but it is more commonly seen in automatic drilling machinery in which it is the workpiece that rotates rather than the drill bit.

In computer numerical control (CNC) machine tools a process called peck drilling, or interrupted cut drilling, is used to keep swarf from detrimentally building up when drilling deep holes (approximately when the depth of the hole is three times greater than the drill diameter). Peck drilling involves plunging the drill part way through the workpiece, no more than five times the diameter of the drill, and then retracting it to the surface. This is repeated until the hole is finished. A modified form of this process, called high speed peck drilling or chip breaking, only retracts the drill slightly. This process is faster, but is only used in moderately long holes otherwise it will overheat the drill bit. It is also used when drilling stringy material to break the chips.