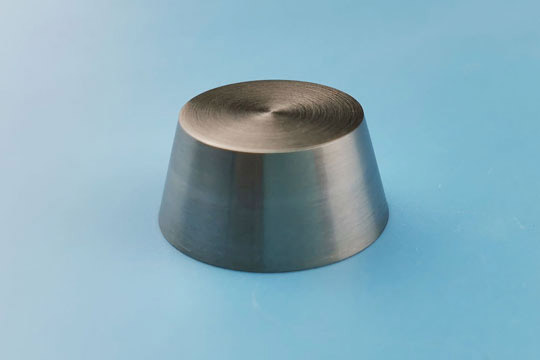

Super Smooth Tungsten Crucible

Main technical parameters:

● Density: 18.5 + 0.2 g/cm3

● Composition: In line with the national standard: 99.95%

● In the surface roughness, Ra is less than or equal to 0.4

● Outer surface roughness Ra is less than or equal to 3.2

● Size: According to customer requirements

Tungsten Crucible Applications

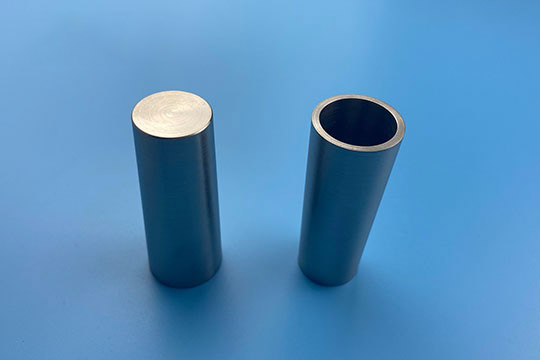

Tungsten crucible is widely used in the sapphire growth furnaces, quartz glass melting furnace, crystal furnace, induction furnace, sintering metal mold of high melting point, electronic beam coating, and rare earth smelting furnace. We supplies all kinds of Tungsten crucibles and other Tungsten parts (including heaters, heat insulation screens, sheets, and supports.). These are used in the process of sapphire growth and rare-earth melting, and we manufacture the products according to customers’ drawings and requirements.

Advantages of Tungsten Crucible

Our tungsten crucible has the advantage of high purity, high-density, low resistivity, high strength, low thermal expansion, erosion resistance. Also, the surface of our tungsten crucible is polished. Therefore, there is no crack, and the inside and outside walls are smooth.

Tungsten Crucible Specifications

We have the world's largest Tungsten crucible, Tungsten tube manufacturing capability, and a maximum diameter of 800mm. The regular density is between 18.0g/cm3~18.3 g/cm3. In some cases, it can reach above 18.7 g/cm3 by our advanced process.

We can offer all the Tungsten parts of the whole hot zone used in current sapphire growing methods.

|

Range |

Diameter(mm) |

Diameter Tolerance (mm) |

Height(mm) |

Height Tolerance (mm) |

Roughness(μm) |

|

Crucible |

10~500 |

±0.05~±0.5 |

10~500 |

±0.2~±0.5 |

Ra≤0.8 |

|

Tray |

10~500 |

±0.05~±0.1 |

10~500 |

±0.2~±0.5 |

Ra≤1.6 |

|

Base |

10~500 |

±0.05~±0.1 |

10~500 |

±0.2~±0.5 |

Ra≤1.6 |

|

Supporting Rod |

10~100 |

±0.05~±0.1 |

10~500 |

±0.2~±0.5 |

Ra≤1.6 |

|

Heating |

Customized |

- |

Customized |

- |

- |

|

Shield |

Customized |

- |

Customized |

- |

- |

|

Rod Product |

Customized |

- |

Customized |

- |

- |