CNC Machining

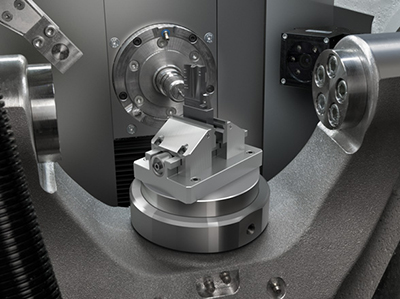

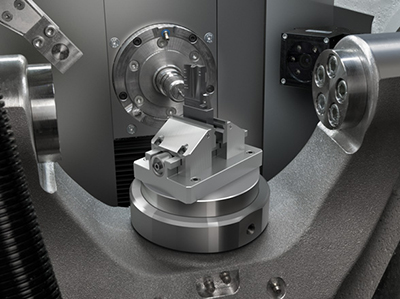

CNC machined center is composed of mechanical equipment and numerical control system, which is suitable for machining complex parts of efficient automatic machine tools. It has a tool changer that can automatically replace the tool, so the workpiece can be able to carry out a variety of processing in a certain range, such as milling, boring, drilling, tapping and thread cutting functions. Its comprehensive processing ability is very strong, and the machining accuracy is higher. For moderate difficulty of batch workpieces, the efficiency is 5 ~ 10 times of general equipment. In particular, it can complete the processing which the ordinary equipment can not be completed. It is more suitable for the complex shapes and high precision single piece processing or the small and medium volume production.

In the process of producing parts in CNC machining center, the CNC system can control the machine tool according to different processes to automatically select and replace the cutting tool. The machined parts after a clamping processed, it will automatically change the spindle speed, feed rate and tool relative to the workpiece of the motion trajectory and other auxiliary functions, continuously machining the surface of workpiece with drilling, counter boring, reaming, boring, tapping, milling and other processes. Because the machining center can automatically complete a variety of processes, so that avoids the artificial operation error, and reduces the workpiece clamping, measurement and adjustment time. Greatly improve the processing efficiency and processing precision, and thus improve the quality of the products.